The benefits of switching from Cold Store freezing to IQF

So – before we start, what is IQF, and why do you need to replace your Cold Store technology with it? In short, IQF stands for individually-quick-frozen, where the individual pieces of the product are kept separate during the freezing process, which is expedited. This, combined with OctoFrost IQF technology, leads to energy-efficient frozen food processing, which has a higher yield and hygiene standard than the alternative.

Meanwhile, Cold Store freezing features food products that are placed in a cold storage unit until it is completely frozen. Given the time investment required, it may be less good for your business processes; it also typically creates large ice crystals in the food during the freezing process, which deteriorates the shape of the product.

Disadvantages in Cold Store freezing

As previously mentioned, leaving food products out for storage until they’re frozen is less time-efficient, which could potentially delay operations, as expanding always requires more freezing space. Another downside is that during the defrosting process, there is drip loss and less palatable taste and texture for the final product – a marked change from their fresh counterparts.

The ice crystal formation is especially detrimental for premium foods as this will negatively affect the aspect of the defrosted product. Advantages of IQF:

IQF fruits and vegetables are far superior in terms of natural appearance, texture, and flavor to their cold store-frozen counterparts. There is no graying, more vibrancy, and hue to the food, which lasts beyond the defrosting process.

Octofrost’s IQF freezing tunnel ensures the frozen food is processed quickly, to capture most of the natural nutrients involved. This is a stark difference from Cold Store freezing, where the large ice crystals tend to pierce through the membrane of the food, which will cause leakage of the intracellular fluid. That tends to make food unappetizing, and a lot of taste and nutritious value is lost as a result.

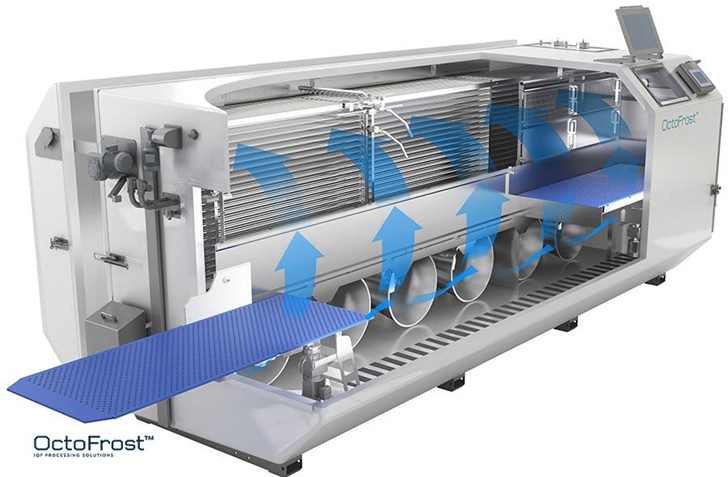

Additionally, there is no longer any clumping together, thanks to Octofrost’s unique bedplate technology. This patented innovation lets cool airflow through the product, keeping it separate while cooling it down. The result is frozen food where each piece is frozen, without sticking together. This helps preserve the initial shape of the food, making it that much more appealing for consumption.

Finally, food safety concerns are obsolete – the bedplates are efficient to maintain and easy to handle, which makes them the perfect contender for on-the-go replacement. They can be washed outside the freezer, which doesn’t interrupt the production process. Octofrost’s IQF equipment is top of the line, in terms of efficiency and yield.

Longevity

Investing in IQF means investing in the longevity of your frozen products, and your business. Octofrost’s unique IQF freezer reduces snow formation so that the food suffers 10 to 20 times less dehydration, boosting its yield and longevity. The minimal presence of ice crystals helps it last for a long time, ensuring a higher shelf life than the competitors.

The industry hygiene standard-exceeding technology makes it simple to stay ahead of the regulations, giving a significant competitive edge. It requires far less labor, as Octofrost’s production line is largely automated and needs only minor human intervention for changing the bedplates. By achieving zero contact between the product and the humans involved, it’s possible to ensure that the highest health and food safety standards are being met by default.

The OctoFrost IQF freezer will be ready for operation within 2-3 days after arriving at the factory, which means your food production can continue even during installation. Clean, sustainable, and energy-efficient, this choice will put you at an advantage in a relatively short amount of time. Don’t wait – your competitors likely won’t.